MICROPOINT PATCH

Our proprietary and patent-pending fabrication technique for making stainless steel microneedles provides us a competitive edge over our competitors. Over the years, we have developed an assorted technique comprising EDM (electro-discharge-machining), precision mechanical grinding and polishing, and electro-chemical de-burring processes. For fabricating hollow microneedles, high-aspect-ratio holes of 50um to 130um can be drilled through the stainless steel microneedles.

Micropoint Patch™ comprises essentially an array of microneedles made of stainless steel, plastic materials or dissolving materials that are used to minimally penetrate the skin creating micron-sized channels, which act as a passage for drug to enter the body. The height of the microneedles ranges from 150um to 1,000um, and the microneedles are spaced at densities of 400-700 needles per cm². Various heights are necessary to cater to different application requirements, namely the material of the microneedles and the body site for the patch.

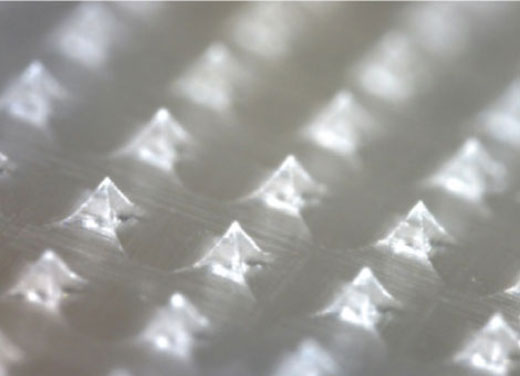

In general, plastic microneedles are made longer to compensate for its bluntness, and they are the more cost effective than their stainless steel counterparts. Among the plastic materials that we use to make plastic microneedles are polyurethane (PU), polypropylene (PP), polyethylene (PE), polystyrene (PS), poly(methyl methacrylate) (PMMA), polycarbonate (PS), liquid crystal polymer (LCP), and so on. Most of these plastic materials (except LCP) are commodity plastics which are extremely low in costs. These wide range of plastic materials have unique surface properties that are suitable for immobilization of specific bio-reagents on the needle surface.

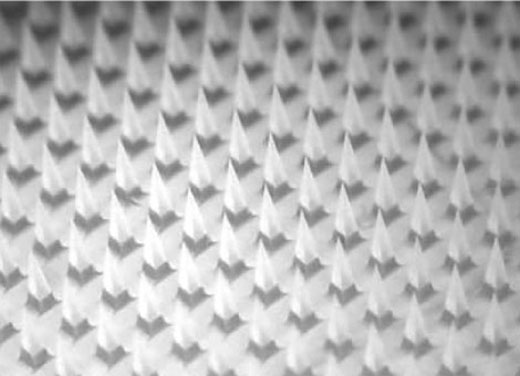

Stainless steel microneedles are the most robust among the existing microneedles and with our proprietary technology the unit cost is reduced to a level where disposable use is practical. The stainless steel microneedle arrays are made from direct machining processes, which involve electro-discharge machining (EDM), grinding, and electro-polishing.

Dissolving microneedles (or dissolvable microneedles) are made of dissolving materials such as hyaluronic acid (HA), polyvinylpyrrolidone (PVP), carboxylmetyl cellulose (CMC) and other bio-digradable materials which rapidly dissolve when they penetrate the skin. These materials encapsulate active ingredients and release them into the skin when they are in contact with the skin.

Micropoint Patch (stainless steel)

Micropoint Patch (plastic)

Polystyrene (PS) microneedles