TECHNOLOGY OF MICROPOINT

Proprietary Manufacturing Technology

At Micropoint Technologies, we make all kinds of microneedles from metal to plastic, from solid to hollow, using our proprietary technologies which efficiently manufacture microneedles at low cost and in high volume. Since every type of our microneedles possesses unique strengths and weaknesses, we at Micropoint are constantly required to match a suitable type of microneedle for specific applications and we will normally develop new technologies in the process.

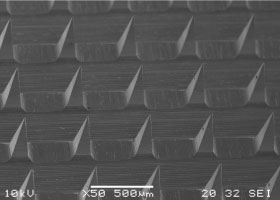

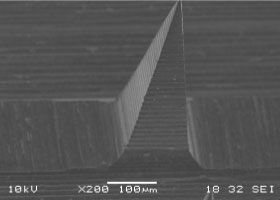

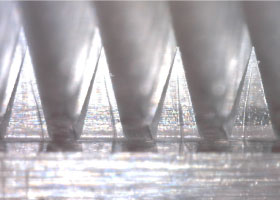

Stainless steel microneedles

Our proprietary and patent-pending fabrication technique for making stainless steel microneedles provides us a competitive edge over our competitors. Over the years, we have developed an assorted technique comprising EDM (electro-discharge-machining), precision mechanical grinding and polishing, and electro-chemical de-burring processes. For fabricating hollow microneedles, high-aspect-ratio holes of 50um to 130um can be drilled through the stainless steel microneedles.

Stainless steel microneedle arrays

fabricated by assorted techniques

SEM micrograph of a sharp

stainless steel microneedle

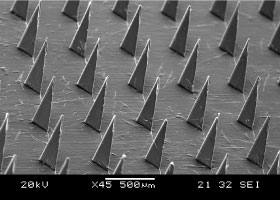

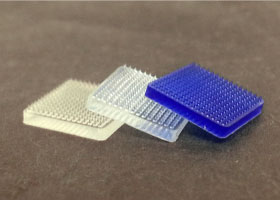

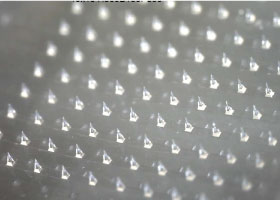

Plastic Injection moulded microneedles

We know the know-how and material-selection knowledge for mass producing inexpensive microneedles for disposable applications. As we know that plastic materials are not as strong as stainless steel, a good plastic microneedle product will have to compromise between manufacturability, material cost and needle sharpness. We at Micropoint have the domain knowledge in specifying the sharpness of the microneedle tips, the height of the microneedles and the strength of the materials to achieve effective skin penetration.

Plastic injection moulded

microneedle patches

SEM micrograph of plastic injection

moulded microneedles

Polymeric microneedles

Harnessing our proprietary technology and domain knowledge in microneedle field, we can make stainless steel master mould with excellent quality in terms of tip sharpness and surface roughness, with very short turn-around time. We also make and supply microneedle templates which can be used to form polymeric microneedles. These microneedle templates made with RTV silicone are directly duplicated from our stainless steel microneedle master moulds.

Polymeric microneedles by

hyaluronic acid

Polymeric microneedles by PEGDA

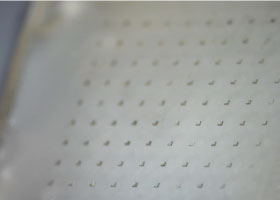

Painless Drug Injection System MPatch™ Mini

A microneedle by itself has very limited use; it penetrates the skin with a depth that normally causes no pain (roughly 200um – 300um deep). However, when loaded with a drug, a microneedle patch (Micropoint Patch™) can be a very effective means to deliver drugs across the skin (this method is generally known as transdermal drug delivery) by creating hundreds or thousands of micron-sized channels on the skin. This allows drugs coated on the needle surface to diffuse into the skin effectively. We actively seek pharmaceutical collaborators in developing a drug-coated Micropoint Patch™.

Our new painless drug delivery platform called MPatch™ Mini is developed for transdermal or intradermal drug delivery applications. Most microneedle products have the drug coated on the surface of the microneedles; this inherently exposes the drug to the penetration resistance which leads to incomplete drug delivery in which a portion of the coated drug is detached from the needle surface and is delivered outside of the skin. In our MPatch™ Mini, the drug is impregnated 50um – 100um in the tips of dissolvable microneedles made of hyaluronic acid. Since the insertion depth of the microneedles is between 200um – 300um, the impregnated drug will be delivered completely. The impregnated drug does not have the detachment issue as experienced in coated microneedles. The dissolvable microneedles with drug-impregnated tips are rapidly inserted into the skin by a spring-loaded applicator to ensure consistent skin penetration, and the minimum wear time in the skin is normally 10 seconds.

MPatch Mini Applicator and

dissolvable microneedle patches

100x magnified picture of the

dissolving microneedles before use

Penetrated skin site by

dissolving microneedles

Plan view of the fully

dissolved microneedles

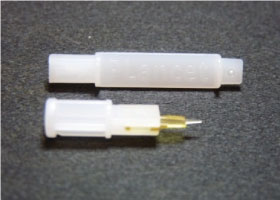

Plastic Needle Technology for Blood Sampling (Lancets)

Based on the microneedle manufacturing technology principle, we developed our Plastic Needle Technology which produces plastic needles in an extremely efficient manner. These plastic needles are less invasive and softer compared to the conventional stainless steel needles. One medical application for these plastic needles is plastic tip (plastic-tipped) lancets for micro-blood sampling. This is a green technology where the manufacturing is very clean and the recyclability is very practical.

Twin-shot moulded PLancet blood lancet

Safety lancet incorporating a PLancet

In addition, the polymers can be made of sustainable source instead of fossil fuel (hydrocarbons), which helps reduce considerable greenhouse emissions. These bio-derived plastics are chemically and physically identical to conventional plastics. According to an official source, the production of bio-plastics (namely polyethylene, PE) removes 2.5 metric tons of CO2 from the atmosphere for every ton of PE produced.

We actively seek medical device companies in developing advanced blood sampling devices for POC (Point-of-Care) blood tests.